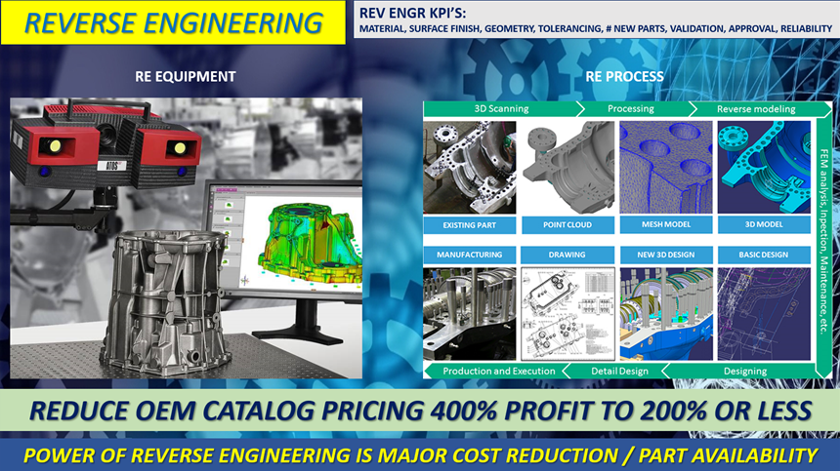

Reverse Engineering is a vital capability to compete in today's ever changing markets seeking to reduce Material costs in every industry. The name of the game is being able to utilize equivalent new parts in Fit, Form and Function that are reliable, safe, affordable and more readily available for use. This involves developing Engineering Reports and Drawings to obtain approvals for the Material, Surface Finish and Geometrical Tolerances for key parts critical-to-quality (CTQ) for significant Top Level Assembly components. In doing so, an appropriate selection of a representative sample of new parts and destructive testing of used parts is conducted to obtain Metallurgical identity of the materials and processes in which the part is made.

All the major player global OEM's are impacted by Reverse Engineering with many Aftermarket Repair sources using alternate approved parts at vastly reduced prices that are equal or better in performance and quality.

Engineered by DOBBS has over 20 years experience practicing Reverse Engineering working directly with the major players in the Reverse Engineering market and successfully implementing alternate parts saving as much as 200% cost from OEM Catalog pricing. It is not uncommun on multi-billion dollar engine contracts with long-term agreements (LTA's) that the Material cost driver is 80% of the program cost making Reverse Engineering an absolutely essential component of long-term program success and profitability.